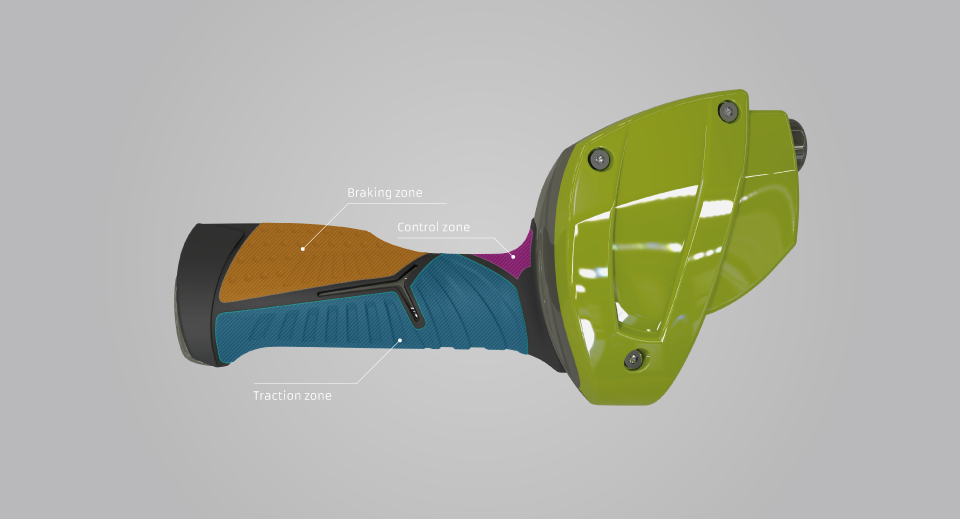

Technical grip zones

INOVELI handles have many ergonometric elements that can be split into three zones: traction, control and braking zones.

The traction zone is the area subjected to forces during the vehicle’s traction or acceleration stage. During these phases, all fingers, expect the thumb, are used to compensate the vehicle’s traction force. We worked on the grip's design so that it provides maximum grasp for the fingers during these phases.

The control zone allows the thumb an optimal position and freedom of movement so it can smoothly control the throttle. The control zone includes a flat area supporting the thumb’s movements against the handle and a hollow area designed for thumb’s muscle.

The handle’s braking zone is used by the hand’s palm during braking and decelerating phases. This zone is flat in order to decrease the palm’s pressure and enhance the hand’s control on the handle during these phases.

The traction zone is the area subjected to forces during the vehicle’s traction or acceleration stage. During these phases, all fingers, expect the thumb, are used to compensate the vehicle’s traction force. We worked on the grip's design so that it provides maximum grasp for the fingers during these phases.

The control zone allows the thumb an optimal position and freedom of movement so it can smoothly control the throttle. The control zone includes a flat area supporting the thumb’s movements against the handle and a hollow area designed for thumb’s muscle.

The handle’s braking zone is used by the hand’s palm during braking and decelerating phases. This zone is flat in order to decrease the palm’s pressure and enhance the hand’s control on the handle during these phases.

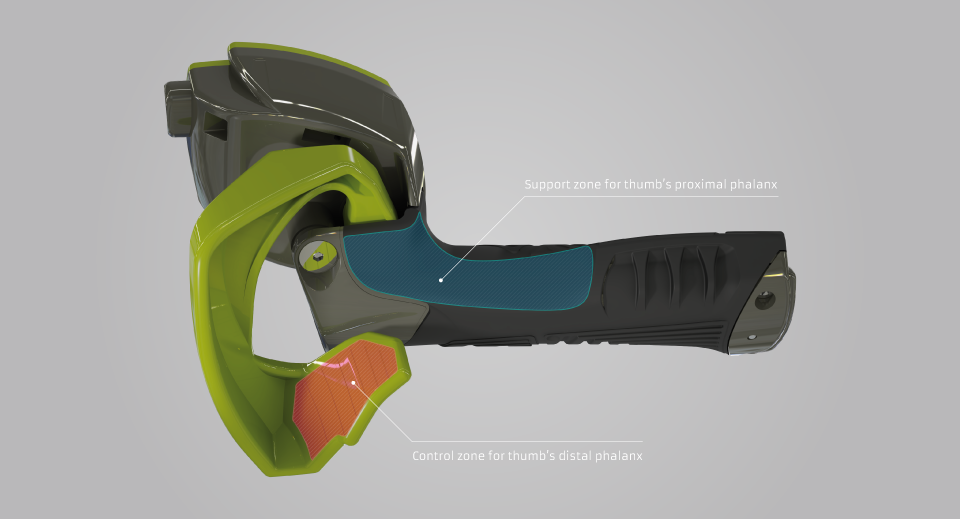

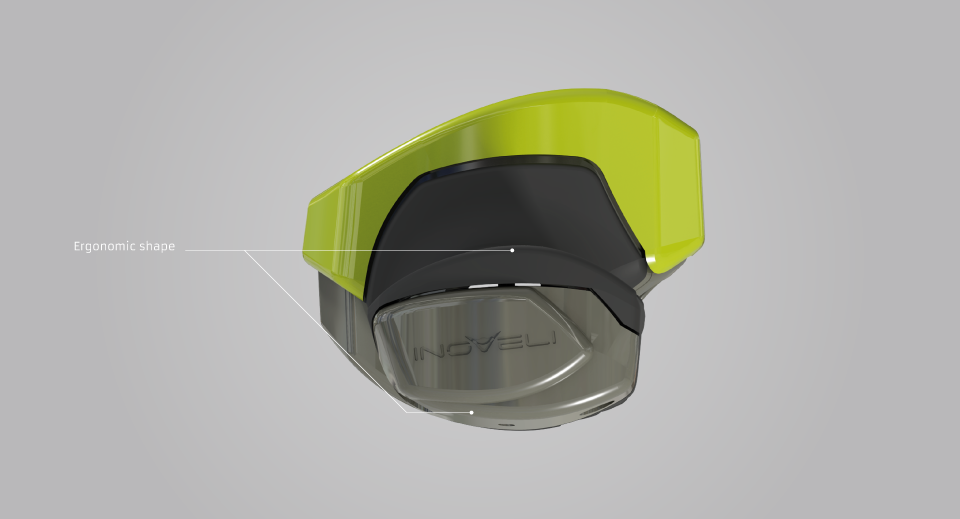

Thumb control ergonomics

The INOVELI concept is based on the permanent pressure of the thumb’s proximal phalanx support on the handle which allows prehensility, and on the pressure of the distal phalanx on the trigger’s tip to exercise control. To meet these technical requirements, we have created specific areas for each of the thumb’s phalanges.

A first flat zone, positioned at the back of the handle, allows permanent contact and lateral movements of the thumb along the handle when exercising control.

A second zone on the spatula allows the thumb’s distal phalanx to thrust on the trigger. Streaks have been made to the spatula to allow a better grip of the thumb’s distal phalanx.

Thanks to its ergonomic shape and its important surface, the thumb can activate the trigger whatever the driver’s position is on the vehicle.

A first flat zone, positioned at the back of the handle, allows permanent contact and lateral movements of the thumb along the handle when exercising control.

A second zone on the spatula allows the thumb’s distal phalanx to thrust on the trigger. Streaks have been made to the spatula to allow a better grip of the thumb’s distal phalanx.

Thanks to its ergonomic shape and its important surface, the thumb can activate the trigger whatever the driver’s position is on the vehicle.

Palm Support

The palm’s support zone has three distinct functions: improving comfort, increasing the handle’s control when braking and helping relieve the driver’s muscular tension. With permanent support for the hand’s palm, the driver can naturally rest his/her hand on the handle and therefore reduce the fatigue in his/her fingers and forearms.

Moreover during braking or deceleration phases, the palm rests perfectly on this large area, which allows better control of the handle and reduce the specific pressure on the palm thus avoiding blisters.Finally, the palm’s support contributes to the handle’s flattened shape which allows the anti-rotation effect of the hand and thus diminishes the squeezing efforts.

These different functions of the palm’s support make it a major part of our ergonomic handle particularly appreciated by all users.

Moreover during braking or deceleration phases, the palm rests perfectly on this large area, which allows better control of the handle and reduce the specific pressure on the palm thus avoiding blisters.Finally, the palm’s support contributes to the handle’s flattened shape which allows the anti-rotation effect of the hand and thus diminishes the squeezing efforts.

These different functions of the palm’s support make it a major part of our ergonomic handle particularly appreciated by all users.

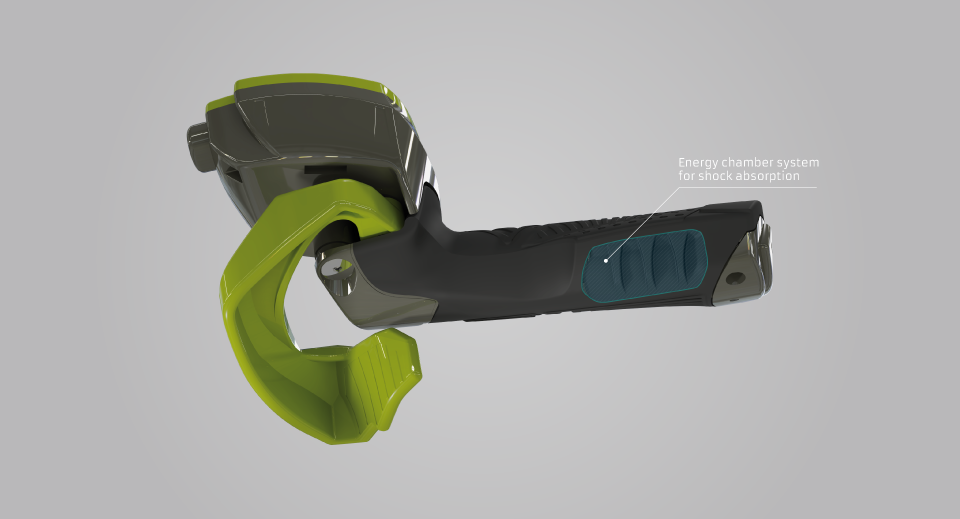

Energy dissipating chamber

The handle incorporates an innovative system which dissipates shocks’ energy. To dissipate the energy from shocks, a cavity is made in the handle’s grip.

The shocks to the hand travel to the palm support, ripple through the cavity which in turn absorbs the shocks’ energy through its deformation, thus protecting the hand.

The energy dissipated in this chamber is therefore not transmitted to the driver and thereby reduces his/her muscular fatigue.

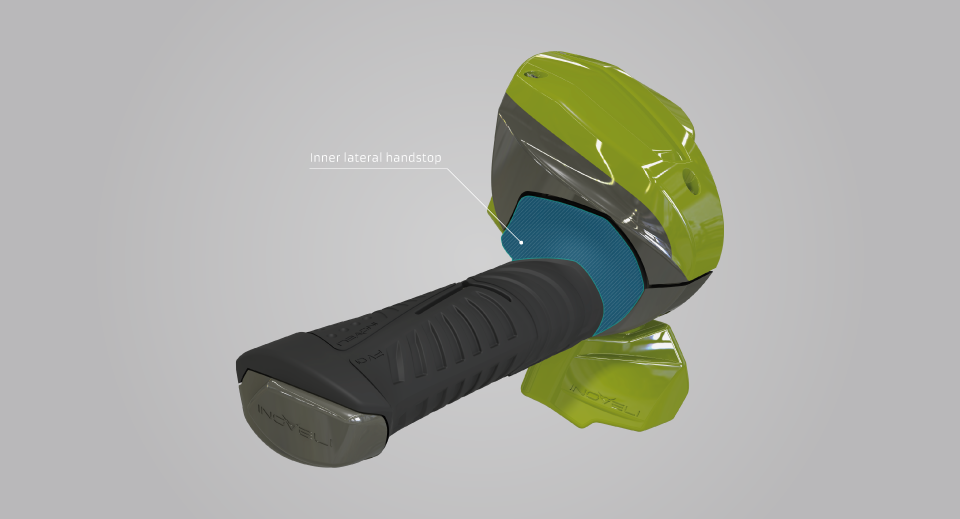

Inner and outer hand-stops

Every INOVELI handles has lateral hand-stops.

A first inner hand-stop is designed to properly place the hand and the thumb’s axial position thus making it easier to activate the trigger. The inner stop allows the pilot’s hand to rest on it in when turning without the pilot needing to squeeze the handle and exercise penalizing muscular efforts.

The external hand-stop has a widened section which allows an axial stop for the hand preventing it from slipping during shocks and turns as it is the case in conventional twisting handles.

Conventional twisting handles require a strong grasp to prevent the hand from slipping. Unfortunately this squeezing enhances the driver’s exhaustion and jeopardizes his/her safety on the vehicle. Our handle with its widened hand-stop provide this outside stop without additional squeezing efforts allowing for a safer grip on the handle.

A first inner hand-stop is designed to properly place the hand and the thumb’s axial position thus making it easier to activate the trigger. The inner stop allows the pilot’s hand to rest on it in when turning without the pilot needing to squeeze the handle and exercise penalizing muscular efforts.

The external hand-stop has a widened section which allows an axial stop for the hand preventing it from slipping during shocks and turns as it is the case in conventional twisting handles.

Conventional twisting handles require a strong grasp to prevent the hand from slipping. Unfortunately this squeezing enhances the driver’s exhaustion and jeopardizes his/her safety on the vehicle. Our handle with its widened hand-stop provide this outside stop without additional squeezing efforts allowing for a safer grip on the handle.

Grip Expansion Zone

A triadic grip expansion zone was designed on top of the handle to allow deformation.

This triad, allowing the grip’s deformation in the three zones (control, traction, braking), participates in the absorption of the mechanical forces affecting the hand and thus gives the fingers a better grasp.

This triad, allowing the grip’s deformation in the three zones (control, traction, braking), participates in the absorption of the mechanical forces affecting the hand and thus gives the fingers a better grasp.

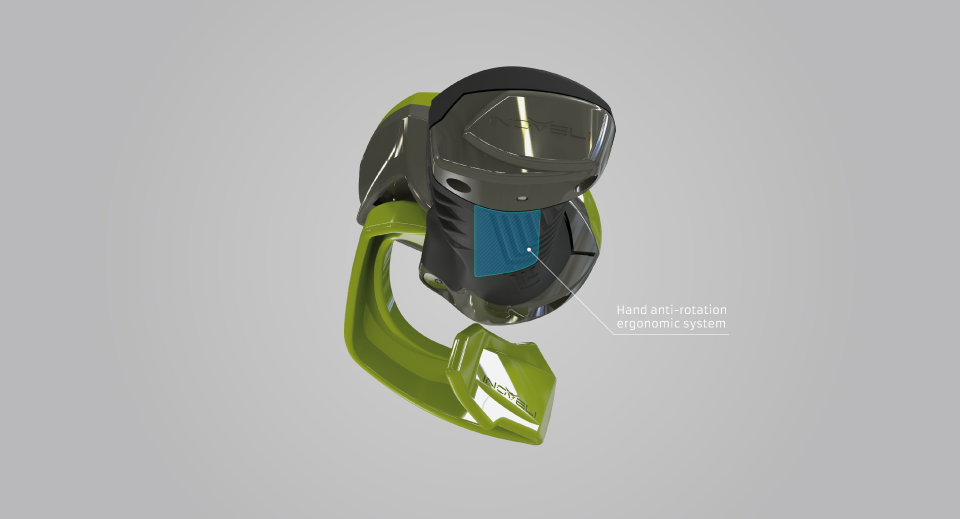

Hand anti-rotation ergonomic system

The handle has been designed to fit the shape of a closed hand. This is why the handle has a slightly flat shape to fit the hand’s natural ergonomics providing therefore a better gras. This flat shape is obtained with two flat zones located above and below the handle.

The palm support, the flat zone on the handle’s upper surface is the first part of the anti-rotation couple. A flat second zone is found under the handle where the fingers are placed. The fingers’ position on that zone is the second part of the anti-rotation couple. The combination of the upper and lower zones has a general anti-rotation effect on the hand whilst it’s on the handle.

Contrary to INOVELI handles, conventional handles are cylindrical, when a closed hand does not form a cylinder. This makes it difficult to have a genuine anti-rotation action on such a cylinder shape. To achieve this, the user has to exert constant squeezing pressure to generate a friction grip. This friction allows to grasp the handle, however it’s very limited due to the handle’s cylindrical shape and to the user’s muscular capacity. The important squeezing effort generates a considerable amount of muscle exhaustion and cramps due to lactic acid.

In conclusion, with our flat handle, the user does not need to exercise extra muscular efforts to generate the anti-rotation force on the handle, which helps decrease the user’s fatigue, cramps, blisters and thus improves performance and safety.

The palm support, the flat zone on the handle’s upper surface is the first part of the anti-rotation couple. A flat second zone is found under the handle where the fingers are placed. The fingers’ position on that zone is the second part of the anti-rotation couple. The combination of the upper and lower zones has a general anti-rotation effect on the hand whilst it’s on the handle.

Contrary to INOVELI handles, conventional handles are cylindrical, when a closed hand does not form a cylinder. This makes it difficult to have a genuine anti-rotation action on such a cylinder shape. To achieve this, the user has to exert constant squeezing pressure to generate a friction grip. This friction allows to grasp the handle, however it’s very limited due to the handle’s cylindrical shape and to the user’s muscular capacity. The important squeezing effort generates a considerable amount of muscle exhaustion and cramps due to lactic acid.

In conclusion, with our flat handle, the user does not need to exercise extra muscular efforts to generate the anti-rotation force on the handle, which helps decrease the user’s fatigue, cramps, blisters and thus improves performance and safety.

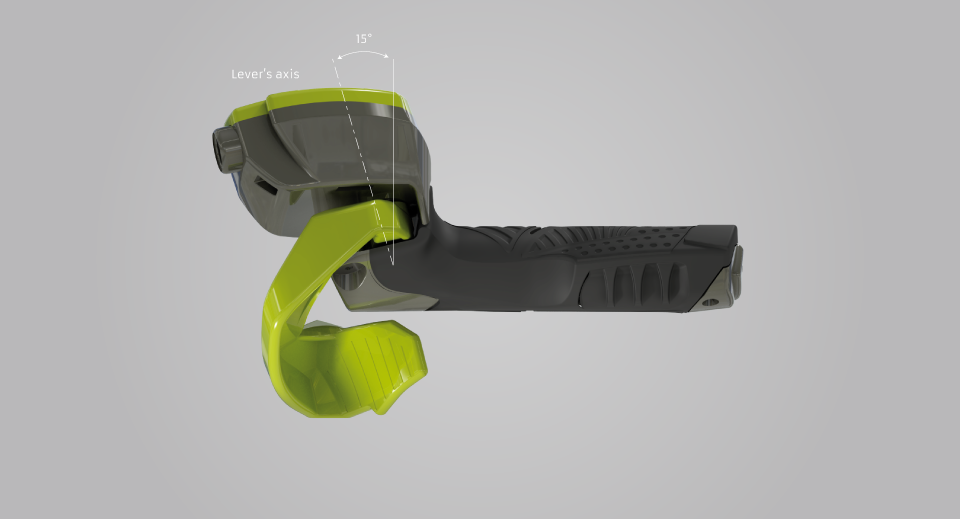

Inclined trigger axis system

The trigger’s axis is a crucial element of INOVELI concept’s ergonomics because it should copy perfectly and naturally the thumb’s movement when it closes on the controls.

After numerous developments we have established a rotation axis for the spatula which can adapt to different hand morphologies.

We angled the axis so that the trigger’s tip moves in an identical plane than the thumb’s using the controls.

These ergonomic developments allow a very natural control of the spatula by the thumb and participate in the fast and natural handling of our accelerator.

After numerous developments we have established a rotation axis for the spatula which can adapt to different hand morphologies.

We angled the axis so that the trigger’s tip moves in an identical plane than the thumb’s using the controls.

These ergonomic developments allow a very natural control of the spatula by the thumb and participate in the fast and natural handling of our accelerator.

Ergonomic Anti-Blister system

Blisters on drivers’ hands happen for two reasons: the skin rubs on the flesh due to the handle’s friction combined with handle pressure zones on the skin and flesh.

Because of shocks, on a cylinder shaped handle, the hand does micro-rotations on the handle, generating micro-frictions leading to blisters. Thanks our handles' flat shape, the hand doesn’t twist anymore, eliminating the micro-rotations and thus diminishing greatly the risks of blisters.

In general, blisters occur because of the lack of support on the cylinder handle which put pressure on specific areas of the hand. Our handle has more than 25% extra support surface compared to a cylinder handle, thus decreasing the pressure on the specific points of the hand and therefore of blisters.

These two specifications on our handles entail a significant decrease of blisters on hands, and thus a better grasp.

Because of shocks, on a cylinder shaped handle, the hand does micro-rotations on the handle, generating micro-frictions leading to blisters. Thanks our handles' flat shape, the hand doesn’t twist anymore, eliminating the micro-rotations and thus diminishing greatly the risks of blisters.

In general, blisters occur because of the lack of support on the cylinder handle which put pressure on specific areas of the hand. Our handle has more than 25% extra support surface compared to a cylinder handle, thus decreasing the pressure on the specific points of the hand and therefore of blisters.

These two specifications on our handles entail a significant decrease of blisters on hands, and thus a better grasp.

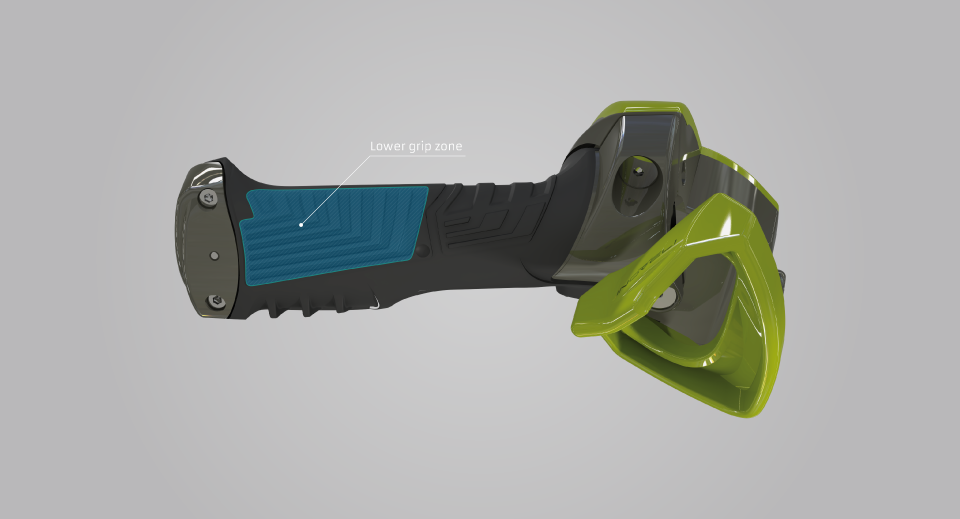

Lower Grip Zone

A streaked longitudinal area was placed under the handle to allow the fingers to have better grip and avoid unwanted rotations of the hand around the handle.

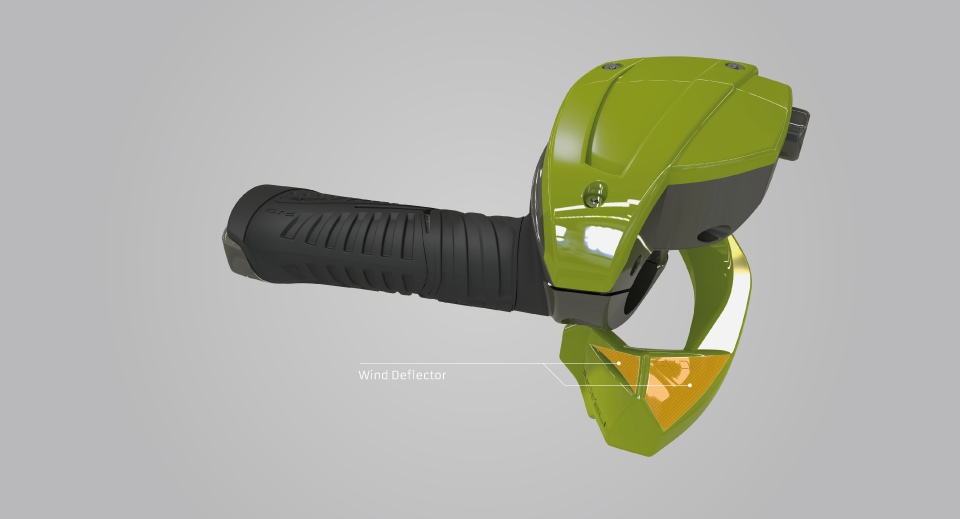

Wind deflector

The thumb is an essential element in gas control, playing an important role in the pilot’s safety and performance. Thus it is important to protect the thumb from outside threats.To do so, we integrated on the lever a deflector to protect the thumb from projected stones, mud, and from cold wind.

By moving, the vehicle generates air, cooling the thumb’s muscles and thus diminishing it’s sensitivity and efficiency.