The world's first convergent throttle handle

The INOVELI throttle system is the world’s first convergent control system. The more you accelerate, the more you close your hand, the more you grasp.

It would seem logical that a throttle works this way as the faster the speed, the more we have to hold on to the vehicle. However, no other existing system uses this principle. For instance, the common handle on scooters and motorbikes where one has to twist to speed is controversial as the faster we go, the less grasp we have on the handle!

This fundamental dimension gives a major advantage to INOVELI in terms of performance and safety on the conventional rotation handles.

The INOVELI throttle system is the world’s first convergent control system. The more you accelerate, the more you close your hand, the more you grasp.

It would seem logical that a throttle works this way as the faster the speed, the more we have to hold on to the vehicle. However, no other existing system uses this principle. For instance, the common handle on scooters and motorbikes where one has to twist to speed is controversial as the faster we go, the less grasp we have on the handle!

This fundamental dimension gives a major advantage to INOVELI in terms of performance and safety on the conventional rotation handles.

Extreme gas command accuracy

Our system allows for a better precision and sensitivity of the vehicle’s power control thanks to the thumb's use.This specificity stems from the thumb’s biological abilities to be both precise and powerful. This ability to move with precision comes not from the thumb’s specific muscles and tendons, but mostly from the way the thumb is controlled by the brain. Indeed, a large section of the brain is used only for controlling the thumb allowing therefore to better analyze data coming from the thumb and granting the thumb more sensitivity than to other fingers.

The other fingers, like the index used for jet-skis, have limited brain and muscle resources, which explains why they’re less sensitive or able to activate different mechanical elements.

As for wrist control, the region in the brain dedicated to this task is almost nonexistent. This explains a poor sensitivity and an inability to perform precise tasks. In order to compensate this physiological issue, powerful retracting springs are used in twisting handles; however, this is not very precise and greatly enhances the muscular effort and exhaustion.

Total insensitivity to shocks

Our accelerator handles are totally insensitive to shocks thanks to the permanent contact of the thumb’s proximal phalanx on the handle.

The permanent grasp in our concept means that the thumb isn’t sensitive to outside mechanical perturbations (shocks, jumps, vibrations, whoops...). Therefore, the thumb cannot move in an inopportune way and generate unwanted accelerations as it is the case with other accelerator control systems.

With our handle’s specificity, the user precisely controls and at all times the throttle control giving the user a unique control and safety.

The permanent grasp in our concept means that the thumb isn’t sensitive to outside mechanical perturbations (shocks, jumps, vibrations, whoops...). Therefore, the thumb cannot move in an inopportune way and generate unwanted accelerations as it is the case with other accelerator control systems.

With our handle’s specificity, the user precisely controls and at all times the throttle control giving the user a unique control and safety.

No incidental commands in strong acceleration phases

Our accelerator system is not only a convergent system, allowing the grasp to tighten as speed rises, but it also has a significant characteristic: it fully and physically dissociates the speed control from grasp. This allows the driver to maintain the handle, whilst using the speed control and not be hampered by the vehicle’s acceleration.

The conventional rotating handle, however, is a diverging system, associating grasp to the control handle. The more the pilot wants to hold on, the harder the retracting spring in the control should be. The user is faced with a dilemma: s/he has to choose between ease of control or grasp. Moreover, the rotating handle system is also divergent, meaning that the more the pilot accelerates, the less s/he can hold on. This leads, in strong acceleration phases, to the pilot trying to hold on as s/he compensate the vehicle’s acceleration leading to a pulling force, twisting the handle and speeding even more, which is extremely dangerous.

With the INOVELI system, this problem is no longer an issue and allows the pilot to control his/her speed and his/her vehicle, even in case of strong acceleration.

The conventional rotating handle, however, is a diverging system, associating grasp to the control handle. The more the pilot wants to hold on, the harder the retracting spring in the control should be. The user is faced with a dilemma: s/he has to choose between ease of control or grasp. Moreover, the rotating handle system is also divergent, meaning that the more the pilot accelerates, the less s/he can hold on. This leads, in strong acceleration phases, to the pilot trying to hold on as s/he compensate the vehicle’s acceleration leading to a pulling force, twisting the handle and speeding even more, which is extremely dangerous.

With the INOVELI system, this problem is no longer an issue and allows the pilot to control his/her speed and his/her vehicle, even in case of strong acceleration.

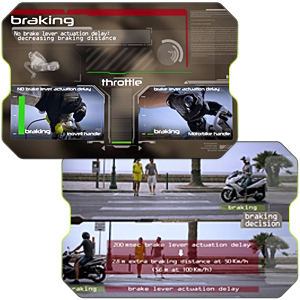

No latency in activating the brakes

With the INOVELI’s accelerator system, the fingers are always on the brake lever and this, whatever the user’s control on the throttle.

To keep fingers on the brake lever at all times eliminates the latency to activate the lever found on rotating handles.

With rotating handles, the user attempts to keep his fingers on the brakes to anticipate braking. Yet, once the decision to brake is taken, the user has to wait for the throttle control to return to idle before starting to activate the brake lever.

A professional racer can activate very rapidly the brake lever (i.e... in little less than 200ms). At 50 Km/h, these 200ms latency corresponds to a distance traveled of 2.8m before the braking action may occur. At 100 km/h this additional distance is obviously doubled, at 5.6m. This latency time increases the braking distance and thus affects the pilot’s performances and above all safety.

Thanks to INOVELI's system the user has no latency for braking enjoying a significant increase in performance and safety.

To keep fingers on the brake lever at all times eliminates the latency to activate the lever found on rotating handles.

With rotating handles, the user attempts to keep his fingers on the brakes to anticipate braking. Yet, once the decision to brake is taken, the user has to wait for the throttle control to return to idle before starting to activate the brake lever.

A professional racer can activate very rapidly the brake lever (i.e... in little less than 200ms). At 50 Km/h, these 200ms latency corresponds to a distance traveled of 2.8m before the braking action may occur. At 100 km/h this additional distance is obviously doubled, at 5.6m. This latency time increases the braking distance and thus affects the pilot’s performances and above all safety.

Thanks to INOVELI's system the user has no latency for braking enjoying a significant increase in performance and safety.

Inline wrist support to absorb efforts

Our accelerator system maintains a straight wrist and thus better absorbs shocks, which no longer vibrate through the tendons, muscles or ligaments, but through the bone structure.

To keep the wrist inline allows not only to eliminate muscular and tendons strain, but also for the arm to push inline on the handle allowing a better control of the handlebar.

This specificity has been enhanced by an ergonomic handle which prevents the hand rotating and helps maintain the wrist inline. Tendons and ligaments are no longer put under stress as it is the case with a rotating handle.

To keep the wrist inline allows not only to eliminate muscular and tendons strain, but also for the arm to push inline on the handle allowing a better control of the handlebar.

Accelerating is possible in positions

The INOVELI accelerator system allows the user to execute and control perfectly the acceleration control regardless of the user’s position on the vehicle.

Indeed, the trigger handle is totally accessible for the thumb, regardless of the hand’s position on the handle. This allows considerable latitude for the pilot’s longitudinal or lateral movements on the vehicle.

A rotating handle uses a more complex biomechanism, requiring the combination of many different movements. Unfortunately rotating the wrist rotation to accelerate also requires a significant rotation of the elbow and shoulder. The combination of these three biomechanical rotations hamper the pilot’s movements on the vehicle. By speeding, these articulations quickly reach biomechanical limits, which lock the driver’s position on the vehicle meaning s/he will have to change the acceleration if s/he wants full mechanical mobility.

Moreover, on a motorcycle, the wrist’s axial rotation decreases its biomechanical lateral torsion ability and hence the driver’s lateral capacity.

With the INOVELI accelerator system this issue is not a problem since accelerating only involves the thumb’s joints and as the thumb can access the trigger regardless of the driver’s position, the thumb is able to perform this acceleration command in any position.

Indeed, the trigger handle is totally accessible for the thumb, regardless of the hand’s position on the handle. This allows considerable latitude for the pilot’s longitudinal or lateral movements on the vehicle.

A rotating handle uses a more complex biomechanism, requiring the combination of many different movements. Unfortunately rotating the wrist rotation to accelerate also requires a significant rotation of the elbow and shoulder. The combination of these three biomechanical rotations hamper the pilot’s movements on the vehicle. By speeding, these articulations quickly reach biomechanical limits, which lock the driver’s position on the vehicle meaning s/he will have to change the acceleration if s/he wants full mechanical mobility.

Moreover, on a motorcycle, the wrist’s axial rotation decreases its biomechanical lateral torsion ability and hence the driver’s lateral capacity.

With the INOVELI accelerator system this issue is not a problem since accelerating only involves the thumb’s joints and as the thumb can access the trigger regardless of the driver’s position, the thumb is able to perform this acceleration command in any position.

Grip symmetry on both handles

Our accelerator system allows an extremely strong grip of the right hand due to the permanent contact of the proximal phalanx along the handle. As this is also the case on the left handside, we have identical grip ability on both sides.The user thus finds a symmetry of control in the two handles, and consequently in the handlebar and the vehicle.

This is absolutely not the case with other accelerator systems. Indeed on other accelerator systems, the user does not have the same gripping ability on the right handle; the driver has to control the handlebar asymmetrically using mostly his/her left arm.

This asymmetry of the handlebar control, and therefore the vehicle, is quite simply demonstrated by the increased wear of the left grip when compared to the right one.

The INOVELI system’s strength of keeping an identical grip on the right handle and the left handle, allows a genuine fine control of the vehicle and enhances the user’s safety and performance.

INOVELI ‘s unique ergonomic handles give you maintaining a surprising comfort and control involved in your performance, endurance but also your safety on the vehicle.