The mechanism of poignéea was designed with the goal to be as compact as possible and also to have the best mechanical efficiency. Indeed it is important that the efforts made by the thumb are not unnecessarily dissipated by friction in the mechanism. For this, we have made a special attention to the guide mechanism and the reduced friction on the different rotating parts. On the axis of the guide mechanism we opted for innovative solutions bearing offset (housing / cover) to have the guide as accurate as possible. On the optimization of friction axis, we made a lot of testing and development have led us to design a specific highly technical level. This bearing is made of a material premium technology that is not only self-lubricating, but also has a very low coefficient of friction. Plus it has no effect "stick-slip" which is characterized by a mild bonding axis at very small displacements. This bearing supports also very dusty or marine environments without generating points jamming. Concerning our other rotating parts, namely nuts trigger and training, they have been designed to provide a robust motion while e as extremely fluid for the user. We also used a resin-based composite Teflon for these gears which can reduce more than 15% friction compared to conventional gear plastic or metal.

The mechanism also understand a specific adjustment of the cable. This allows the grip of the tip of the cable on the drive wheel regardless of the length projecting from the cable. The drive wheel has many slots on the end cap and a plurality of positions of the teeth of the pinion which allow easier adaptation to different vehicles. Preferably the user will choose the housing of the # 1 and the drive gear will rotate slightly to tension the cable. It may then, thanks to its numerous teeth, insert it into the correct angular position. Fine adjustment of the cable will be using the threaded end of the cable and against nut allows blocking.

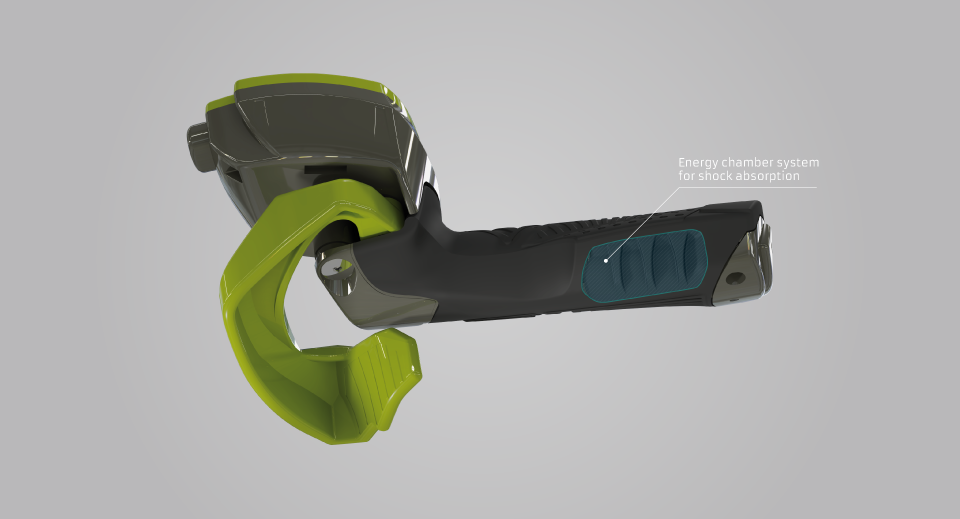

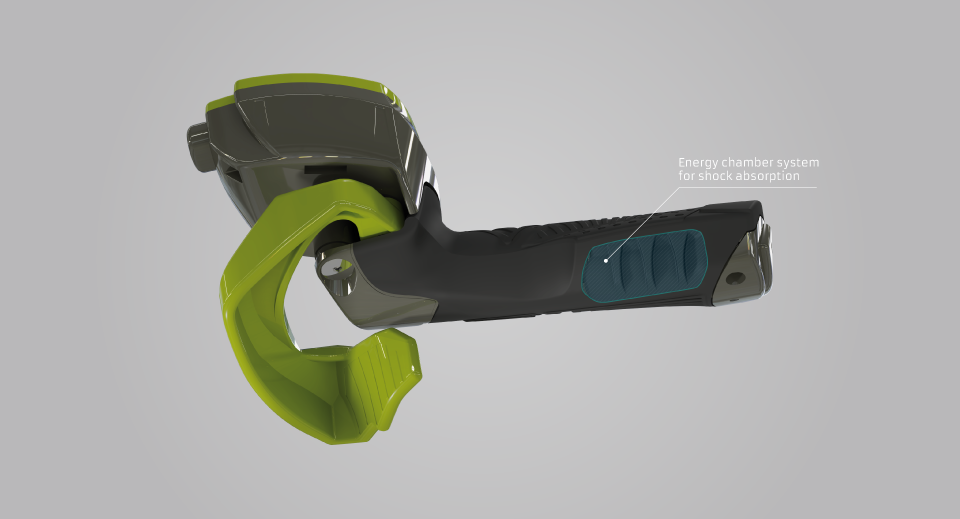

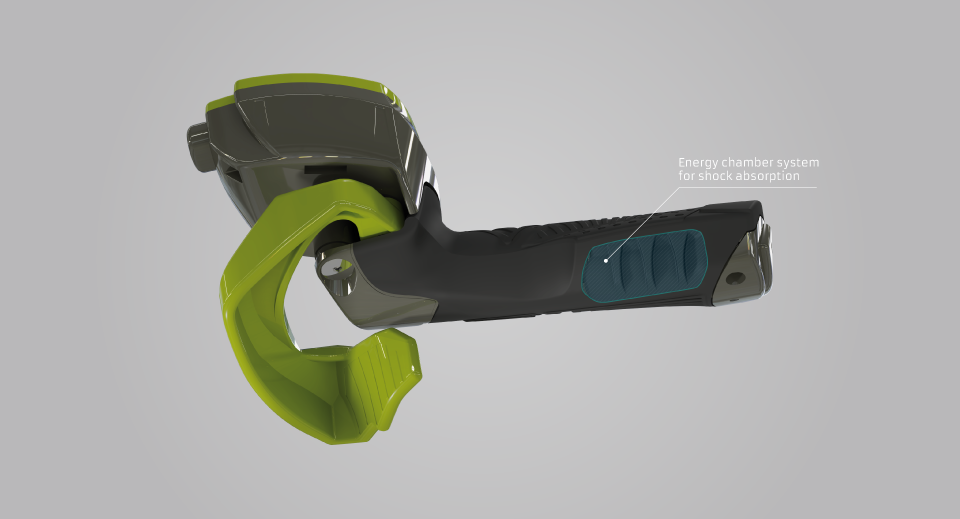

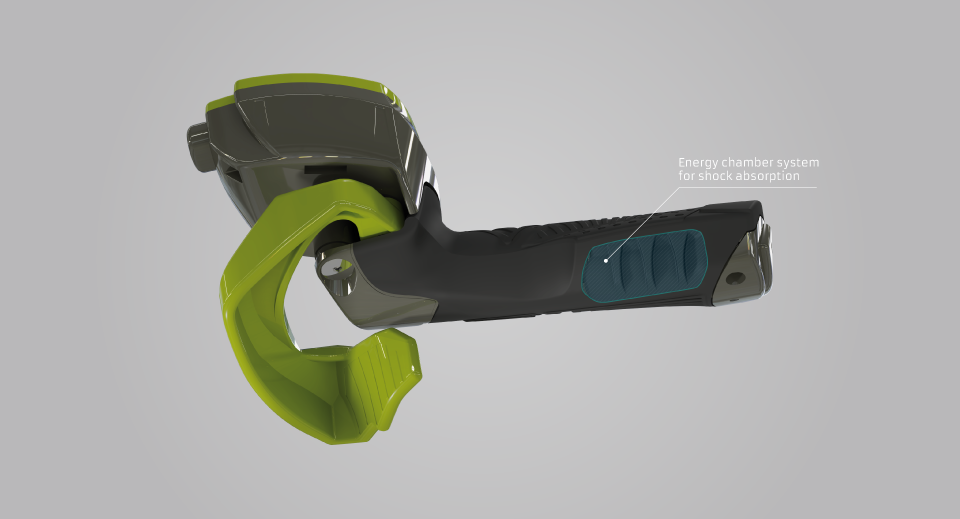

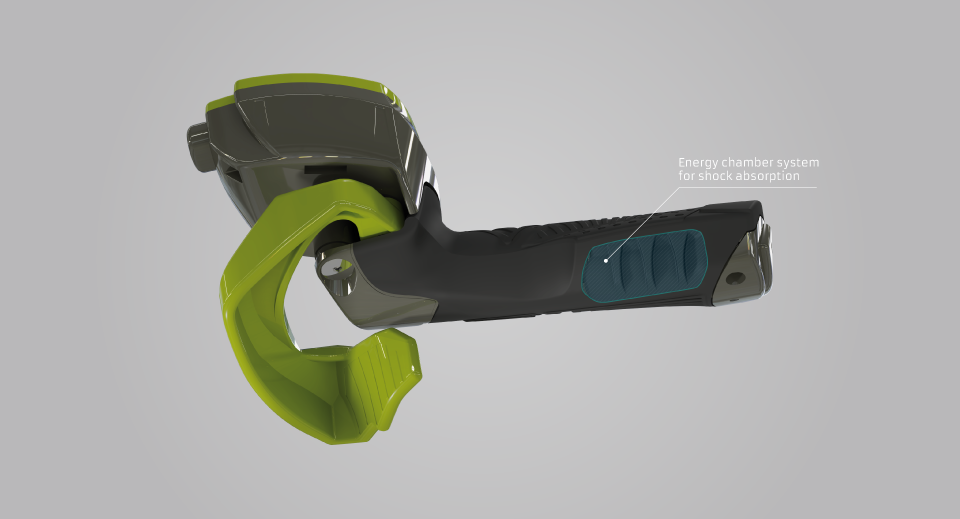

The handles are also made for innovative bi-materials. This technical solution allows the use of two different materials in a single piece, recquiert a high level of expertise in plastic injection correctemment for implementation and significant investments in tooling injection. However because of the desire to INOVELI provide high quality products performance, we have invested in this technology in order to offer the market today handles the first accelerator , operators bi-Matera. These handles are made of a composite material comprising the hard structure of the handle and a flexible and adherent component grip. This solution enables INOVELI handles extremely strong attachment to the handlebars via the composite drive while offering the user a comfortable grip and a touchdown through a precise and flexible grip particu LY member.

The system has many INOVELI handle both technical and ergonomic innovations in particular fixing system handles on the handlebar. That our handles are shaped légèremment flattened to fit the morphology of the hands and it has a palm support, the torque generated by the user these handles is almost two times that he could generate with conventional cylindrical handle. The views of the recurring problems of rotation of the handlebar grip handles with cylindrical it was essential to find a real solution technique that allows real fixing handles on the handlebar without relative motion (rotation / translation). After extensive testing and development, we have chosen the solution locking pin which is first of all a true mechanical solution but also offers easy installation and unalterable. In order to provide our users maximum safety pins are two slots available internal part (housing) and outer (end) of each handle. It is the responsibility and choice of the user to mount or not these pins depending on the use of the vehicle. This system lock pin is an important element of the performance and security of our system because it prevents any rotation or micro rotation of the handle e on the handlebars which would affect the gripping of the handle and thus the vehicle control and safety of the user.

The materials used in our products have been selected ranges prémium materials and solely for their technical performance. The structure of the trigger handle and use thermoplastics composites with high Young's modulus, giving them a great strength to the strain and shock. Thanks to the use of these materials the trigger support tensile forces of more than 100 kg! The sprockets are made by injection of a resin-based composite Teflon which gives it a very low friction coefficient. All metal parts (screws, bolts, ...) are made of a stainless steel A4 Premium supports marine environments. The grip he uses high-tech polymer that provides excellent shock absorption and a very nice touch. Plus it keeps a good grip even soaked in water. Composite thermoplastic resins have also been selected for their ability to withstand UV without altering their mechanical properties and their visual.

Many validation tests are performed on our products to ensure their quality and provide different user an extremely efficient in time and in all conditions. For this we rely on multiple validations in laboratories as well as dynamic tests on vehicles made by experienced pilots. Thanks to our industrial partner SMR, we implemented a very strict specifications based on those of the automakers most rigorous in order to ensure proper functioning of our products in all conditions operation. Regarding laboratory testing here is a list of tests which are made of our products:

• Salt Spray Test

• Test dusty (dust + sand and very fine abrasive)

• Endurance test command (+ 100 000 cycles)

• Test of endurance climate (oven -30 ° C / + 85 ° C)

• Test mechanical rigidity

• Test quality material

Tests on vehicles are mostly done by competition pilots used to develop high-performance products. Dynamic tests are performed on all types of vehicles, from motocross bike or enduro through the scooter, quad biking and jet skiing. We use our procedures from motorsport to validate and develop our technical solutions. Handle INOVELI FV01 is the culmination of over 3 years of such tests on all types of vehicle in all types of extreme conditions.